Slow wire walking, also known as slow wire EDM (Electrical Discharge Machining), is a technique used in precision machining to cut intricate shapes and contours in various materials. This method offers exceptional accuracy and surface finish, making it a popular choice in industries such as aerospace, automotive, and medical.

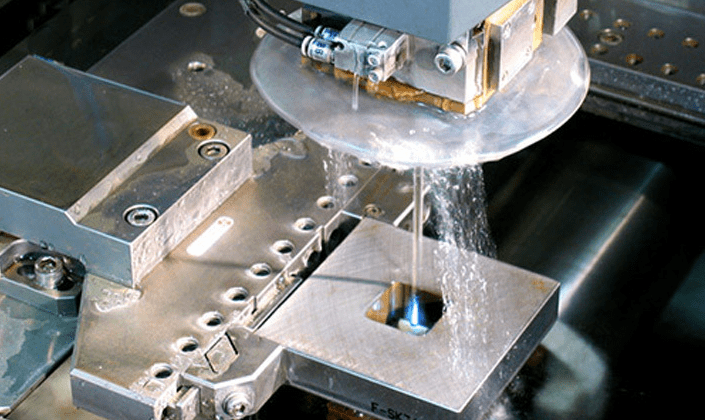

The principle behind slow wire walking involves the use of a thin, electrically charged wire to erode the material being machined. The wire is guided along a pre-programmed path, slowly moving through the material while maintaining a constant tension. This controlled movement allows for precise cuts with minimal distortion or heat-affected zones.

One of the key advantages of slow wire walking is its ability to cut complex shapes with tight tolerances. Whether it’s intricate patterns, sharp corners, or narrow slots, this method can achieve high levels of detail and precision. Additionally, slow wire walking can be used on a wide range of materials, including conductive and non-conductive substances.

Another benefit of slow wire walking is its ability to produce a superior surface finish. The controlled movement of the wire ensures a smooth and uniform cut, minimizing the need for additional finishing processes. This not only saves time but also improves the overall quality of the machined part.

Furthermore, slow wire walking offers excellent repeatability and consistency. Once a program is established, it can be replicated for future production runs, ensuring consistent results and reducing the risk of errors. This makes it an ideal choice for mass production or projects that require high precision and consistency.

In conclusion, slow wire walking is a methodical approach to precision machining that offers exceptional accuracy, surface finish, and repeatability. Its ability to cut complex shapes and achieve tight tolerances makes it a valuable technique in various industries. Whether you need intricate parts for aerospace components or precise molds for medical devices, slow wire walking can deliver the precision you require.